Passionate about continuous mixing

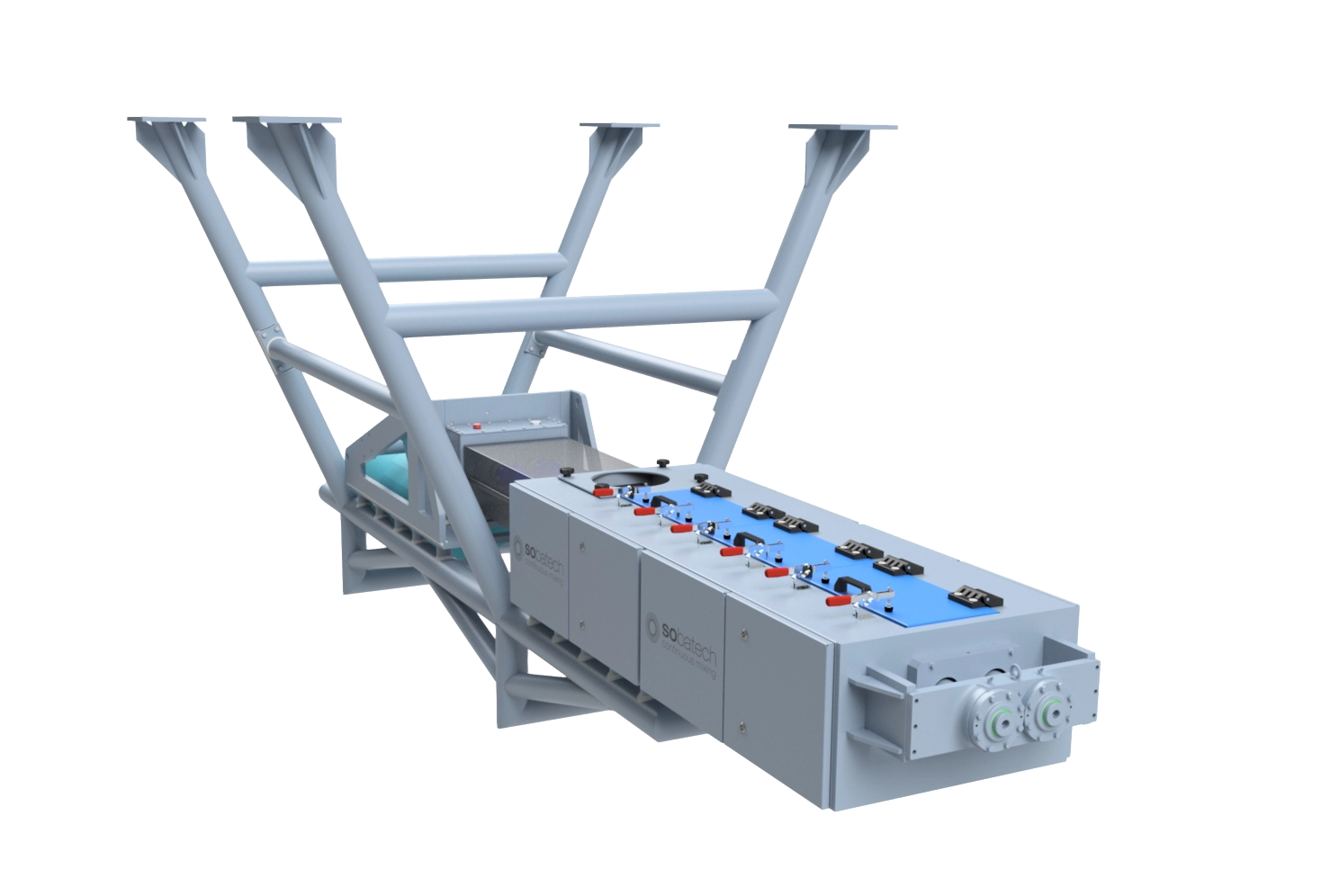

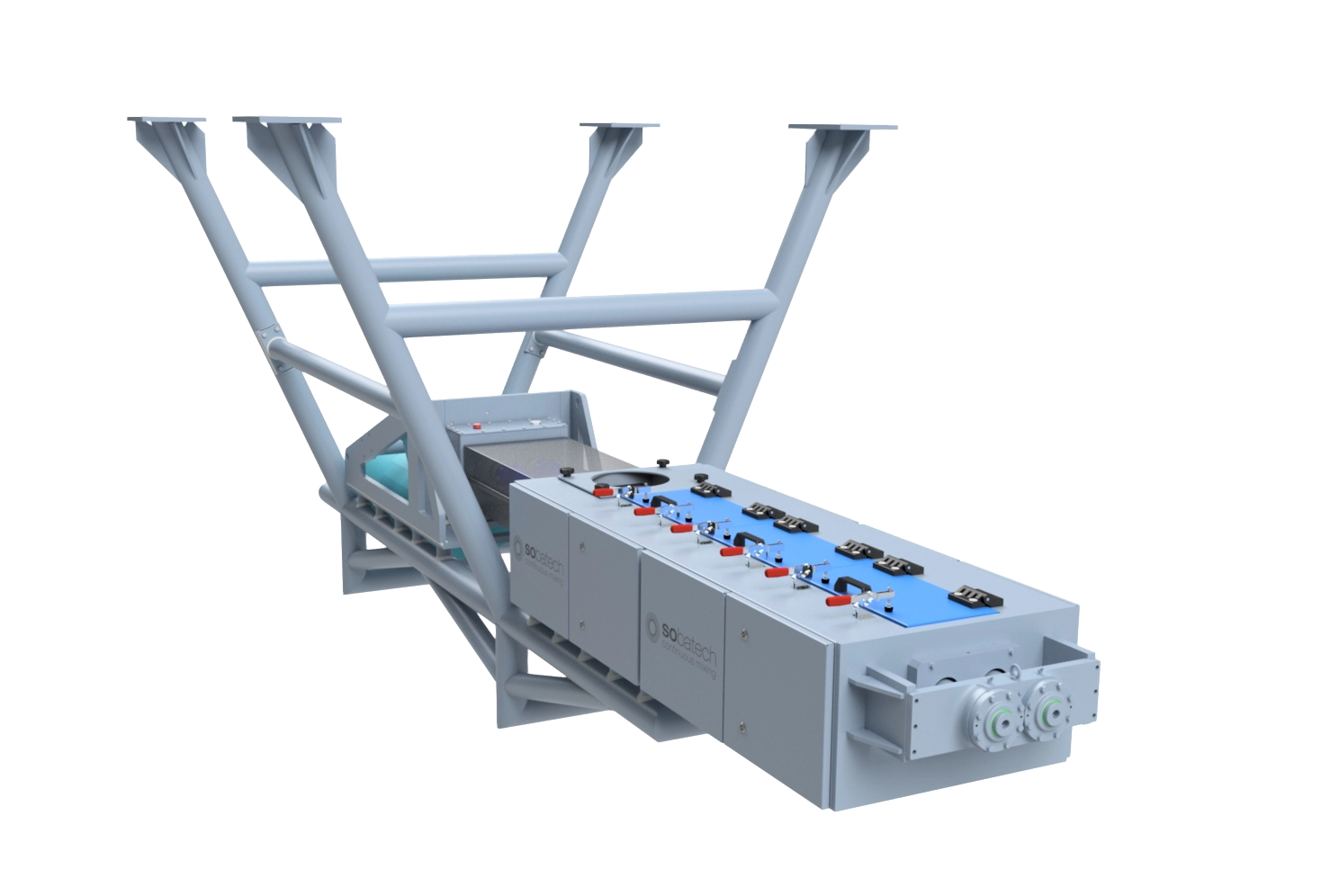

Sobatech is the International leader in designing, manufacturing & commissioning innovative continuous mixing systems for the food and non-food industry. Sobatech’s equipment & expertise helps to simplify your mixing process, reduce labor, cut costs and improve quality consistency.

Discover the future of food processing with Sobatech’s continuous mixing solutions. Designed to enhance efficiency, consistency, and quality, our technologies are perfect for a wide range of food applications. Click below to explore how we can elevate your production processes.

Unlock new possibilities in your industry with Sobatech’s continuous mixing solutions. Whether it is for pharmaceuticals, chemicals, or other non-food sectors, our systems are engineered to deliver precision and reliability. Dive into our solutions to elevate your production processes.

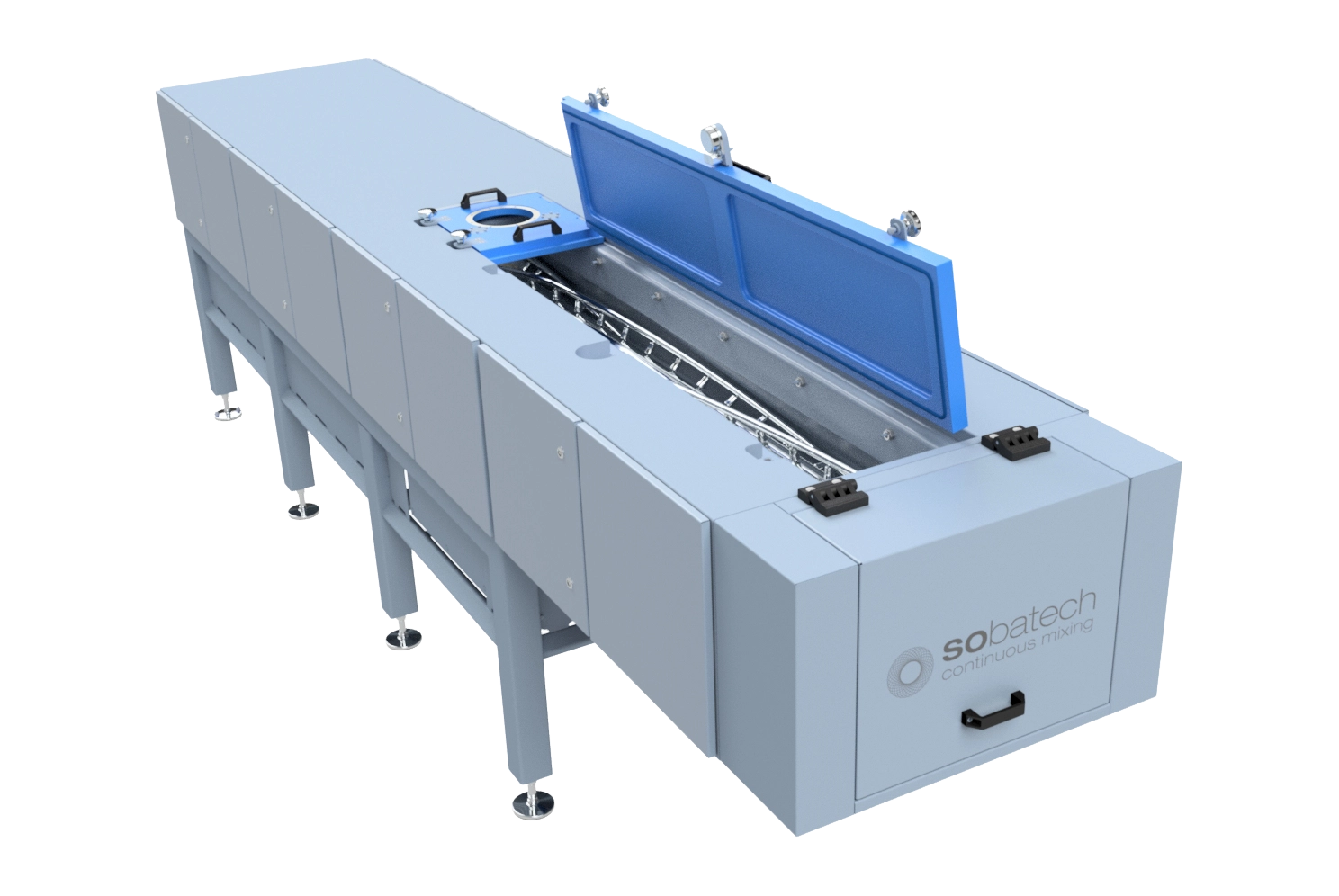

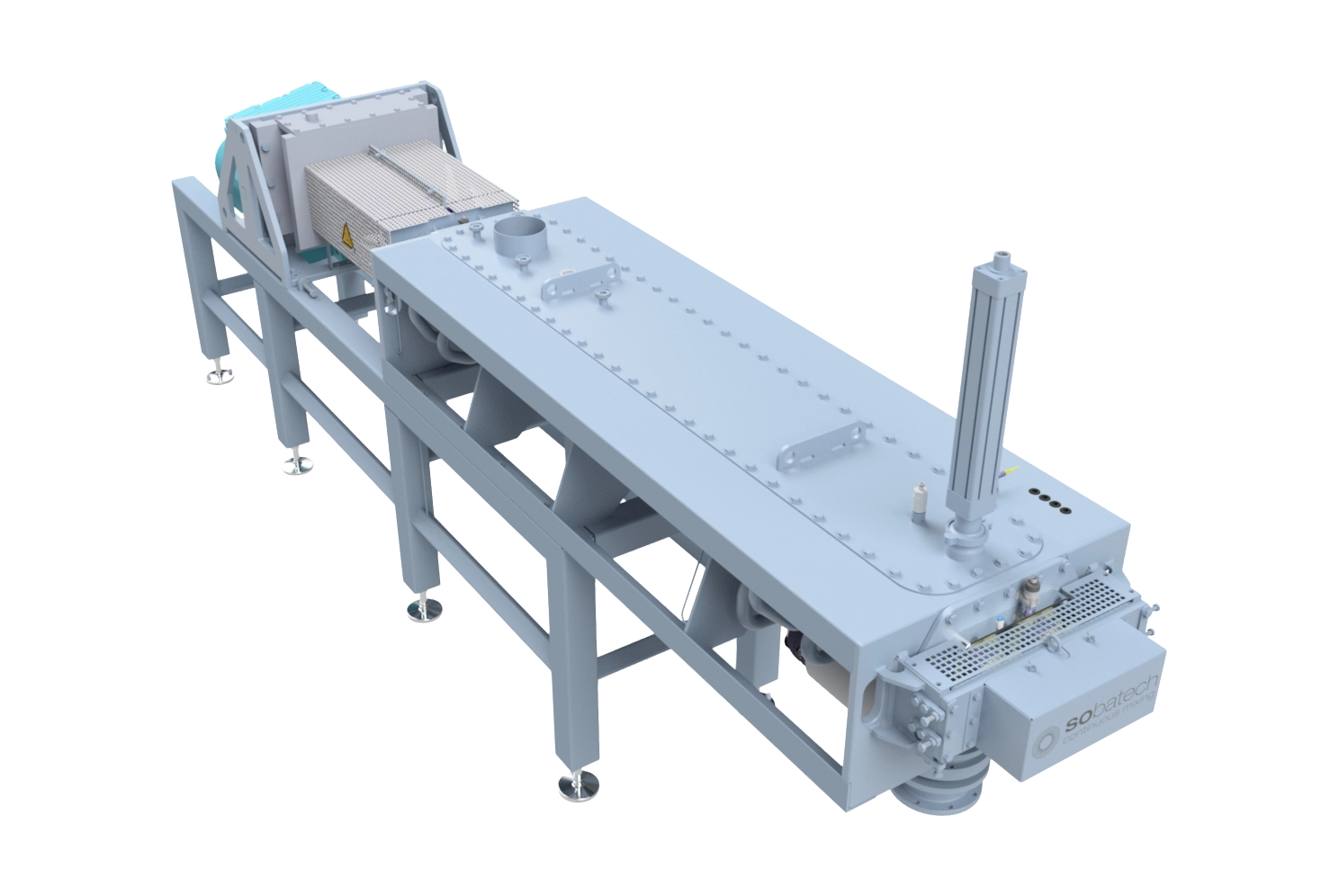

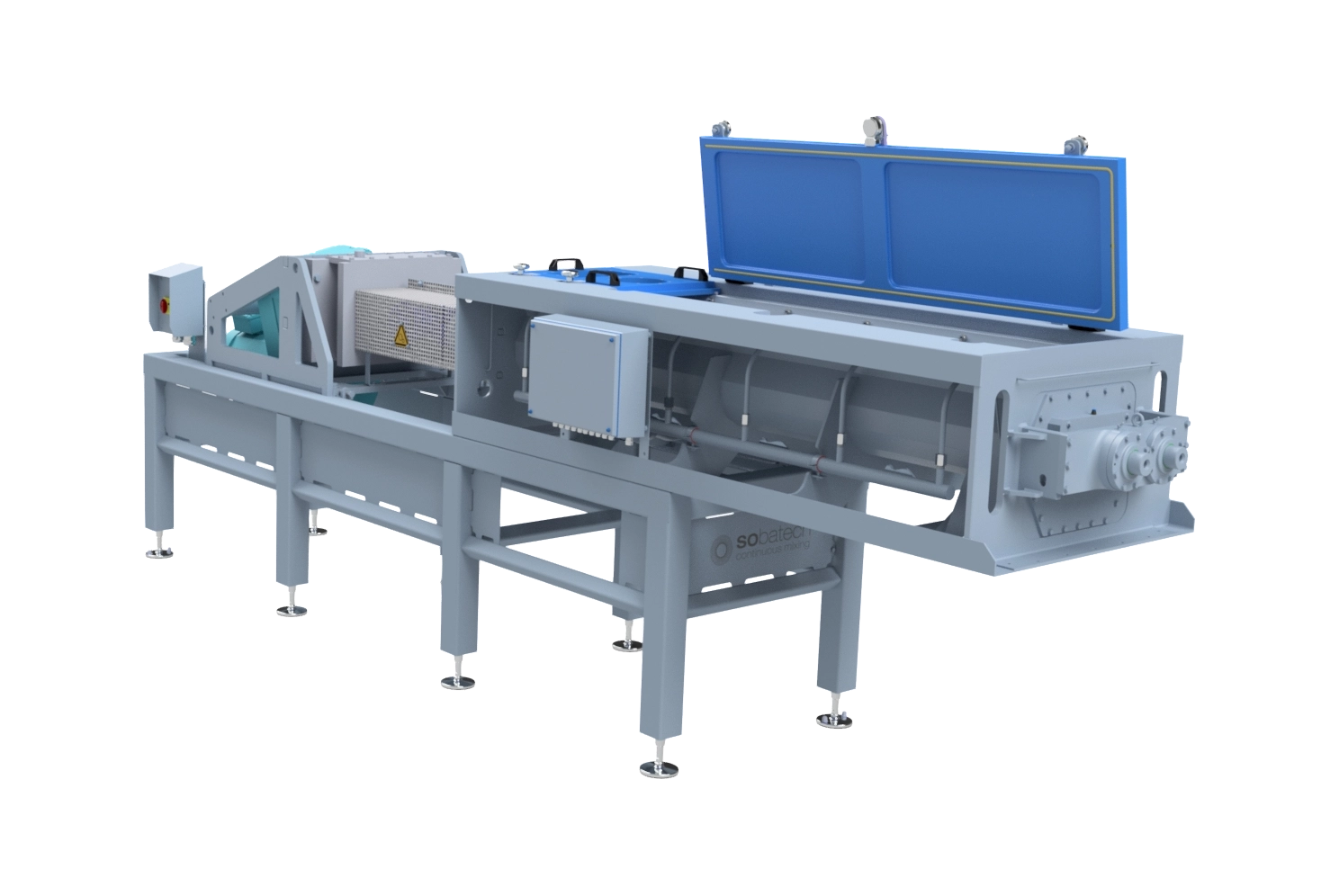

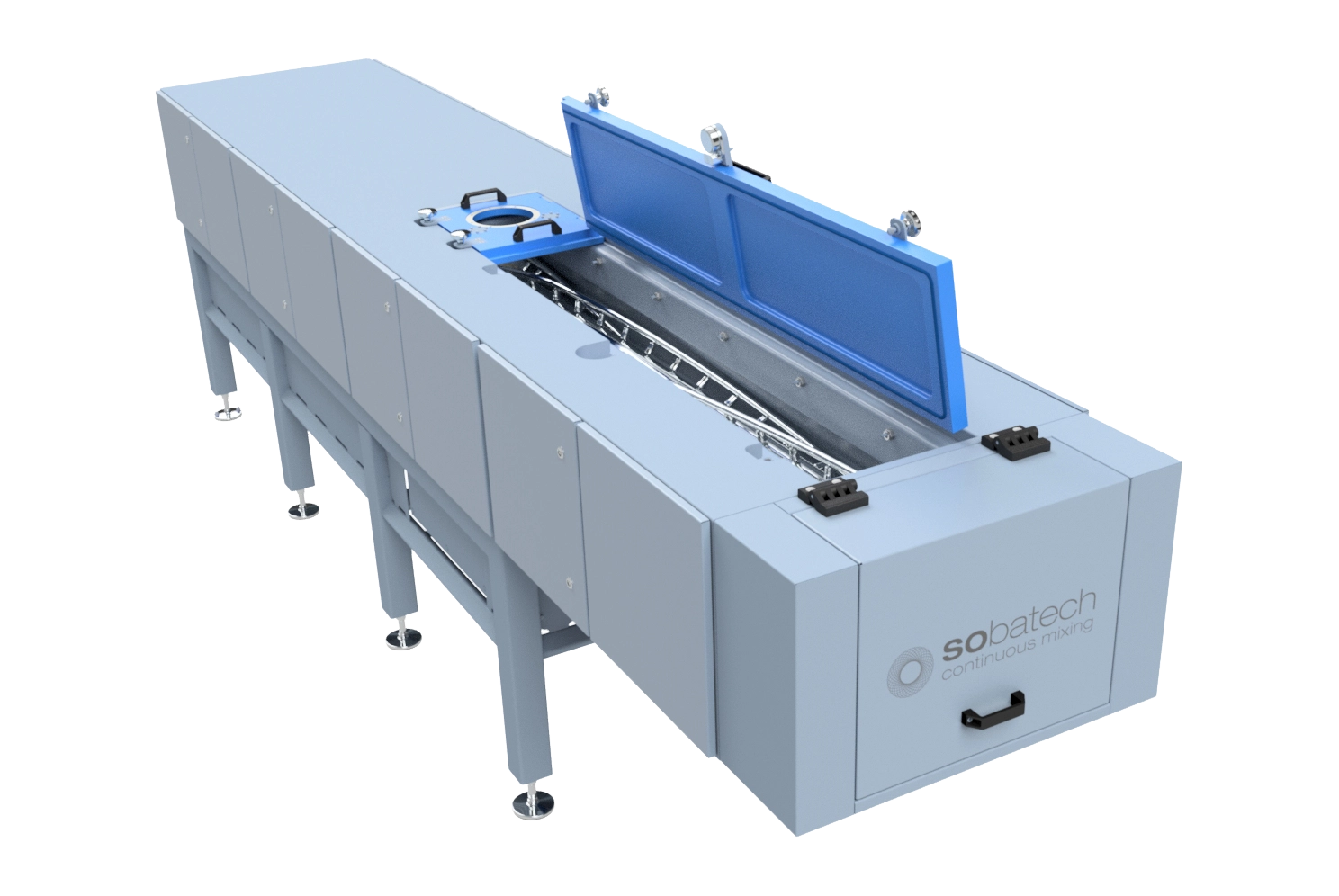

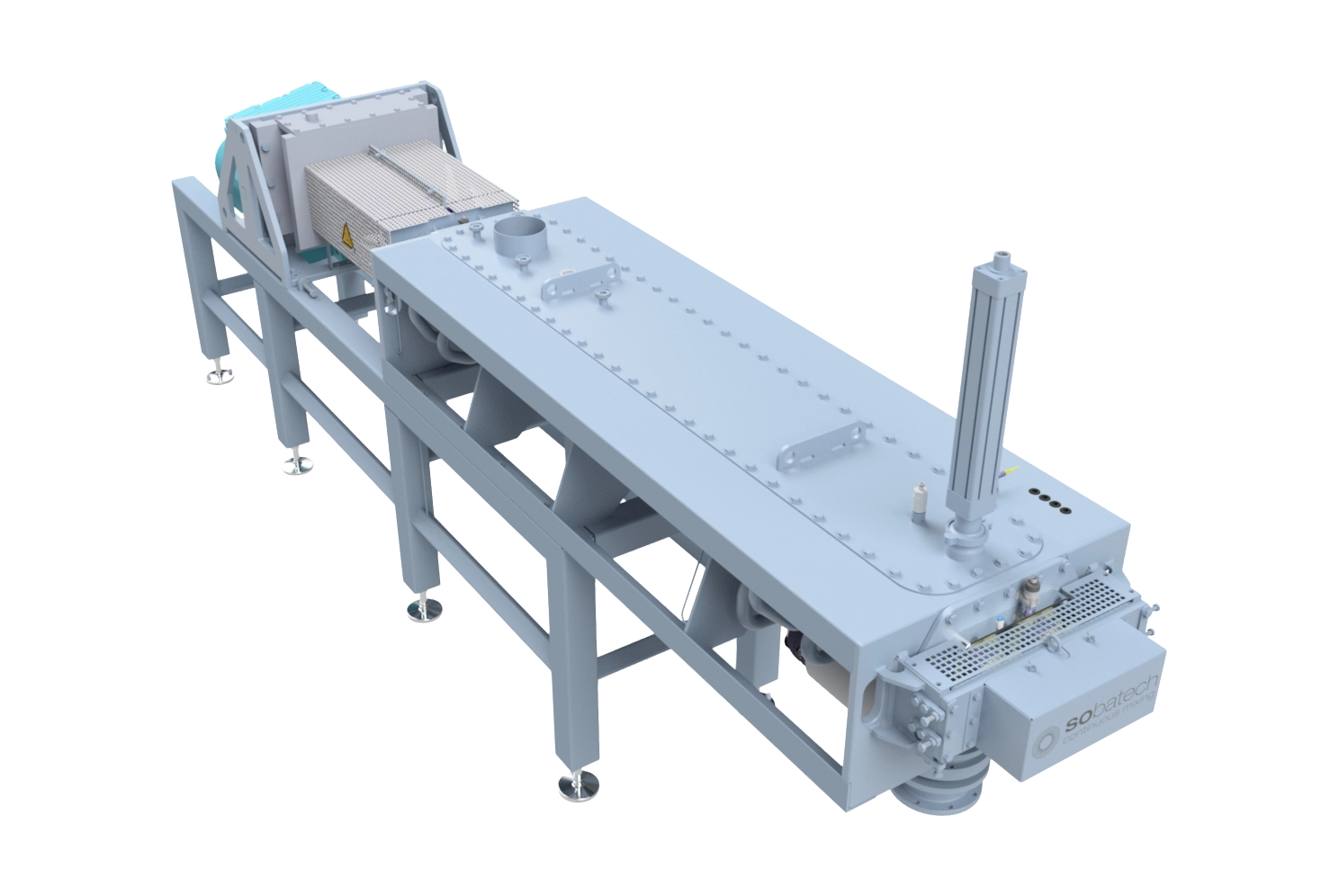

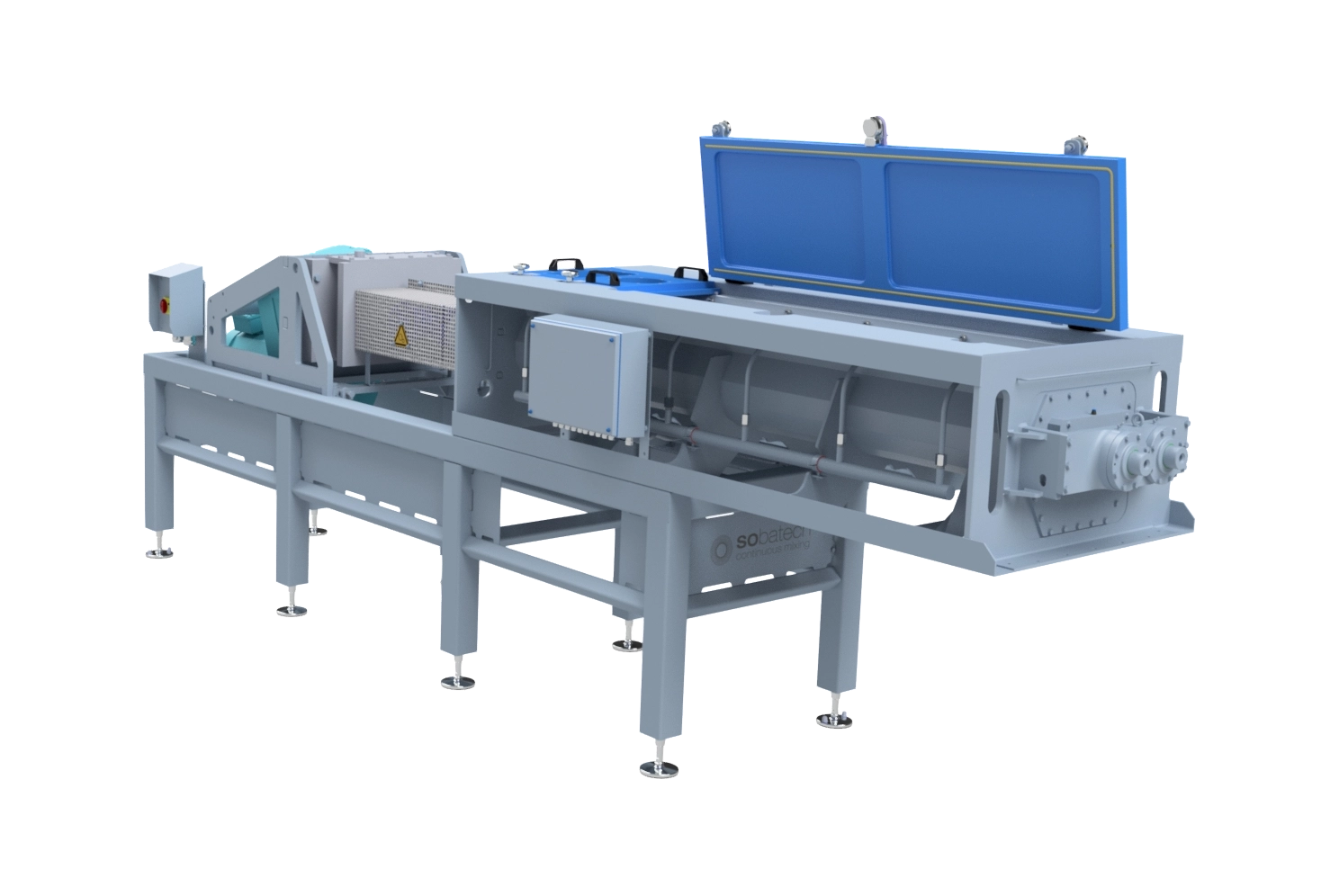

Continuous mixing ensures consistent quality in your production process. Each piece of dough receives the same mechanical treatment, which prevents batch to batch dough variations. Resulting in a reliable final product with less waste and higher efficiency.

Read moreReducing process variations decreases the need for adjustments and minimizes variations in the final product. Sobatech's continuous mixing systems offer total control over recipes, product quality, and development.

Read moreContinuous mixing is a cost-effective solution for production. Sobatech's automated systems lower labor expenses and decrease product waste. The compact design saves space, while efficient energy use enhances sustainability in production.

Read moreDiscover the future of manufacturing at Sobatech's demonstration center. See our innovative continuous mixing systems in action and experience how they can optimize your production line. Whether you want to improve product quality, boost automation, or increase efficiency, experience at our democenter how Sobatech can elevate your production to new heights.

.webp)

Our experts are ready to help you optimize your production process.

Reach out today to discover how our continuous mixing systems can enhance your production process.